Products

Download: Corporate Profile

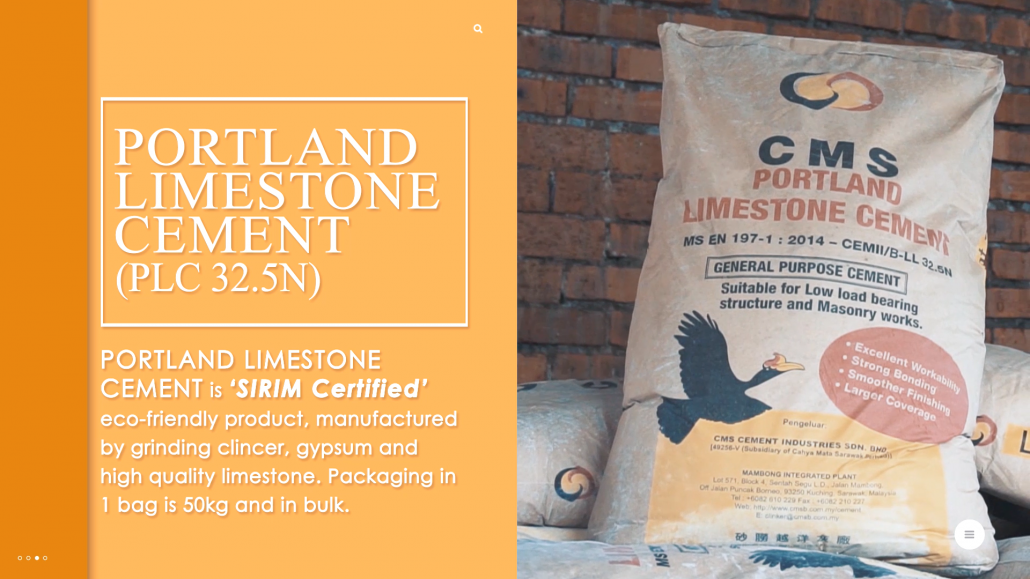

Download: PLC 32.5N Product Brochure

Watch Now: Portland Limestone Cement Mixing Guide Video

What is Portland Cement

Portland Cement (PC) is multi-purpose cement that is most commonly used in general concrete construction. Portland Cement is a grey-coloured dust. When mixed with water, it hardens into the material used for concrete construction.

CMS Cement Sdn Bhd’s PC exceeds the quality requirements specified in the Malaysian Standard MS 522 : Part 1: 1989 Specifications for Portland Cement.

At CMS Cement, quality is guaranteed. CMS Cement is the winner of multiple national and state awards for quality and best practices. Certification of ISO 9001 : 2000 was achieved on 29 December 1998. CMS Cement’s strict quality control at all stages of manufacture as well as stringent testing, control and monitoring procedures ensures the quality of the finished product.

Manufacturing Process and Raw Materials

The raw materials required for the manufacture of PC at CMS Cement are clinker (90%), limestone (5%), and gypsum (5%).

As an integrated cement manufacturer, CMS Cement obtains its supply of clinker from CMS Cement Industries Sdn Bhd and limestone from CMS Quarries Sdn Bhd for both its Bintulu and Kuching plants.

The raw materials go through a pre-grinding process that involve processing through the roller press or “polycom” to compact the mixture into units called “cakes.” These are then processed in the “despol” to loosen the substance before the next step.

The next step of manufacture is the separation process of fine and coarse materials via machinery named the ”tube mill” and the “cement separator”. The resulting grey cement dust is collected by the “main bag filter” and is stored in the cement silos.

Despatch and Delivery

CMS Cement’s PC is available in three sizes: Bulk Tanker (ranging between 20-40 tonnes in volume), one-tonne “Jumbo” bags, and 50kg bags. The journey from the silo to the customer is taken by sea or by road via our appointed dealers and strategically placed depots in Miri and Sibu.